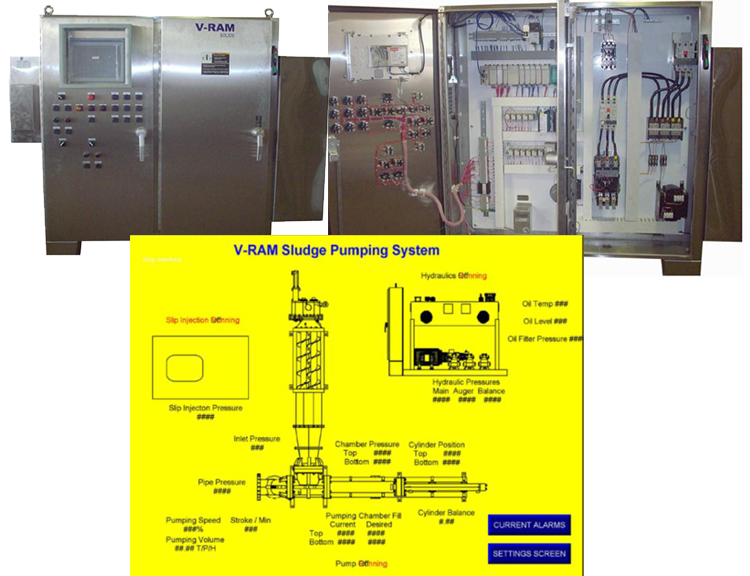

Sludge Control Packages

The sludge control packages are equipped with a PLC used to monitor and control the operation of the

sludge cake pump and pump feeding double auger conveyor system. The PLC automatically and

independently sets and maintains the pumping volume on each cylinder under all changing sludge

characteristics and all pump discharge conditions.

The PLC systems can be intergraded with remote access capabilities so V-RAM technicians can analyze

your system and assist with any changes needed for your system’s reliability and future expansion. No

on-site service technician needed.

The control systems may incorporate the following features and capabilities:

- Monitors oil levels in hydraulic reservoir, in feed auger gearbox and pumping cylinder imbalance.

- Monitors pump performance including pumping rate, cylinder speed and auger speed.

- Monitors oil temperatures and condition of oil filters.

- Logs pump performance information, including total strokes, total pump output and output of each cylinder individually.

- Provides fault indicators for abnormal pumping conditions, low oil levels, abnormal oil temperatures, dirty oil filters, pumping cylinder imbalance, and abnormal storage hopper levels.

- Monitors pumping system component life cycles including pumping chamber strokes, hydraulic system hours, in feed conveyor hours and control PLC hours.

- Control system will be furnished in a NEMA 4X enclosure.

- Control keeps daily totals of volume and current pumping volume and records all pumping volume information.

- Control adjusts screw feed speed on every stroke to maintain pumping volume at the volume the operator sets. Typically we can maintain pumping volume within 1% of desired rate. This not only maintains pumping volume, but runs the screw feed at the slowest speed necessary, thus preventing excessive wear in the screw feeder

All electrical control packages can be UL certified.