Sludge Pumps

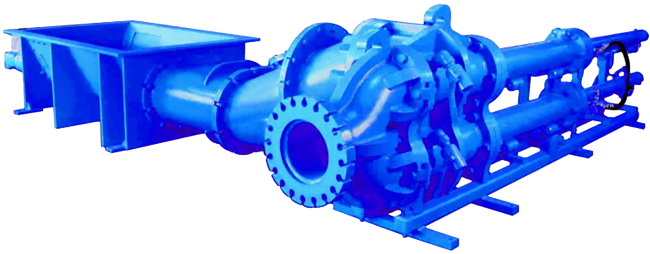

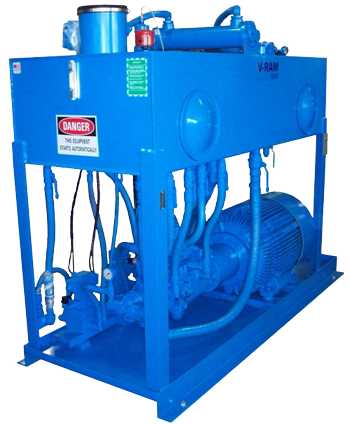

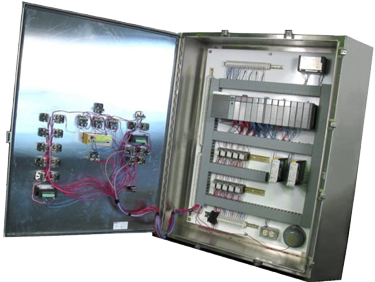

The V-RAM Sludge Pumping Systems are designed for high pressure, high volume and high abrasive sludge pumping 24 hours a day, seven days a week. The Sludge Pumping Systems are used to move sludges with a 12 to 55% solid ratio with pumping volumes ranging from 1 GPM to 428 GPM. Each system is completely designed for particular application and includes the pumping module which includes the double pumping chambers with integrated water chamber and four passive ball valve system, hydraulic unit, double screw in feed conveyor (auger) and control package.

ADVANTAGES

Capability of moving large volumes.

Passive ball valve system that has proven to have at least a five to ten times longer wear factor than the poppet valves.

Replace only the worn seals on the piston ram instead of the whole ram like other competitors.

Eliminates the complex hydraulics used to open and close the four poppet valves in other systems.

Control PLC packages can be intergraded with remote access capabilities so V-RAM technicians can analyze, diagnose and assist with any issues that may arise remotely saving time and money.

Lower maintenance costs.

Reduces clean-up time and costly downtime.